![]()

Carbon Fiber Hood

Project

(last update 04/30/05)

I hope this page helps you understand at

least one

process for making a composite (i.e. Fiberglass, carbon

fiber...) part.

Though this project seems quite large and complicated it really isn't

especially

if you are lucky enough to have friends with the right equipment and

know how.

Jesse and I mostly supplied the labor....lots of sanding!

Before I start, we want to say:

(order defined by process sequence)

THANK YOU Steve and Tom at Beavervalley Mfg. for their modeling expertise and support.

THANK YOU Tom at Temple Systems Inc. for cutting our scoop mold on their large bed milling machine.

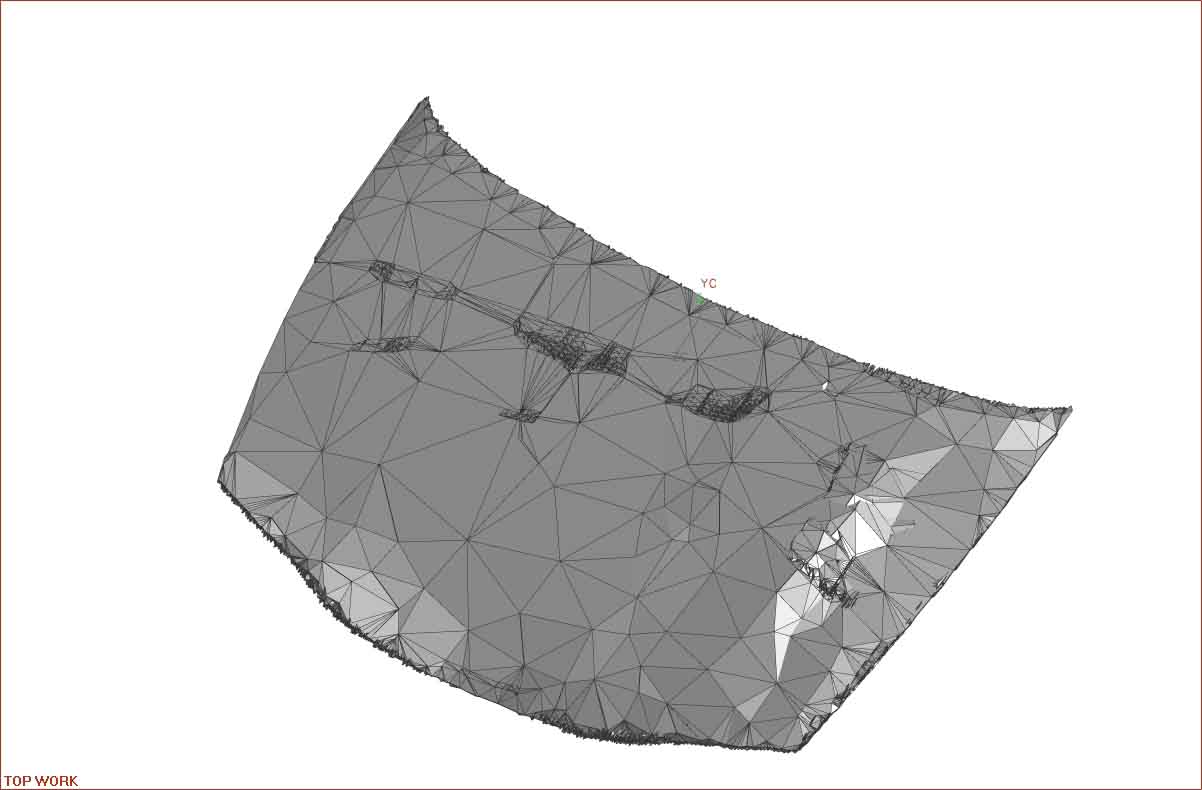

Using a laser scanner like this one Scott scanned the original Talon hood to create a 3D Computer Aided Design (CAD) model.

This is what the scan produced.

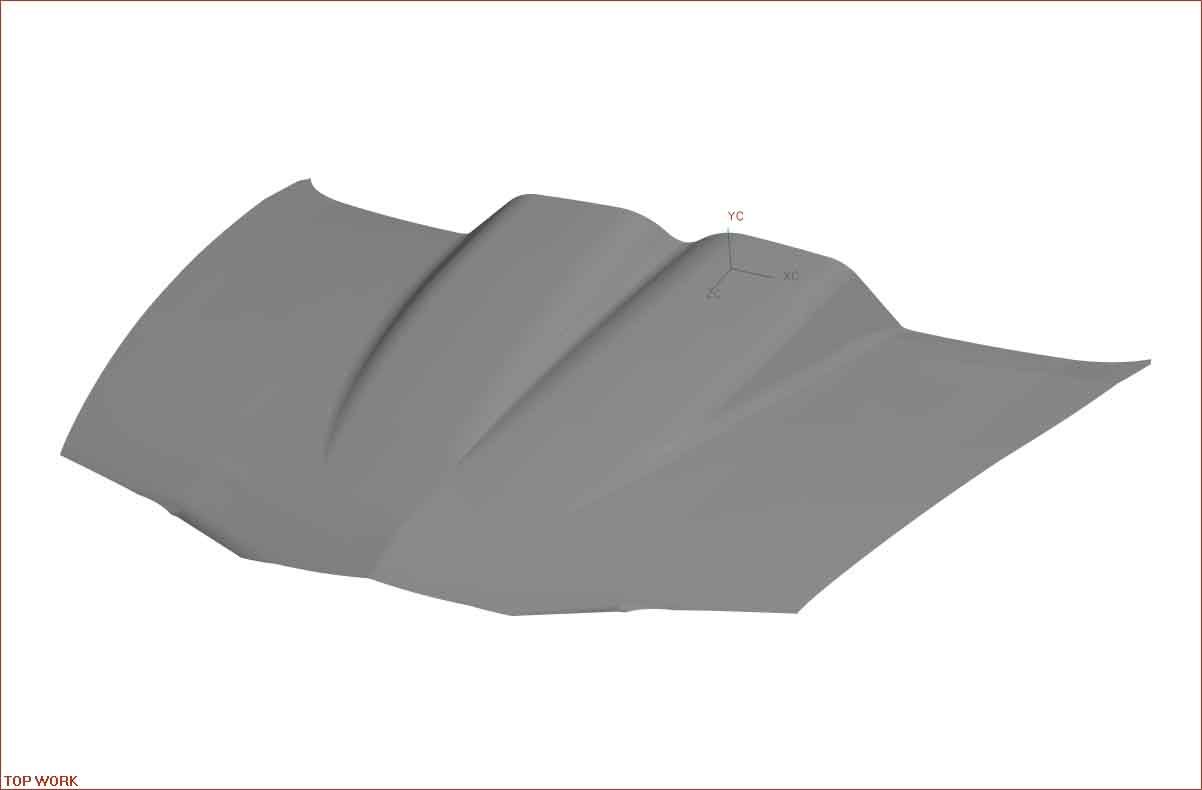

Using a CAD software called Unigraphics and the scan information I created this 3D model concept of the hood and scoop .

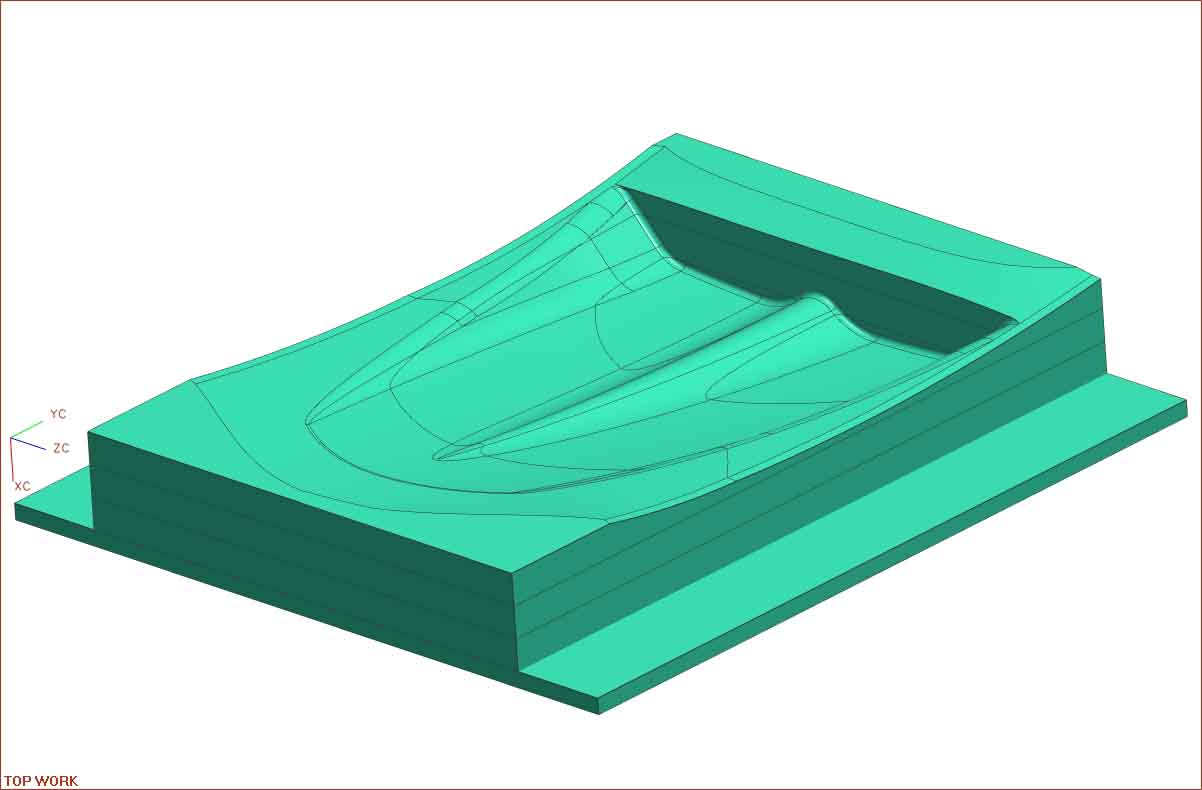

We decided not to machine the whole hood

because we didn’t

want to take up valuable machine time especially since Tom was doing

this as a

favor for us. The illustration above shows the 3D model of the molde

for the scoop only.

Using the 3D model of the hood and scoop

I subtracted it from a solid block and this

is the result. Hopefully, as we proceed thru the process it will become

clear

why we made this mold and how we intend to use it.

I'm excited now! Our foam mold is clamped down and we have started the cutting process. Based on the machine software it will take about 40 minutes to rough cut this down to within 3/16” of the finished surface and another 4 hours to remove that last 3/16” over the whole surface.

Next ->

![]()

Jerry and Nita's

home page / Family Matters

/ Ferret Antics

/ Our

Critters

Gone Hunting

/ Home Theater

/ Talon Project

![]()

![]()

You can reach us at: ferretantics@earthlink.net

![]()

This page was created and maintained by

Jerry

at

Sensible Design Solutions